What are PLCs? Expert Guide to Programmable Logic Controllers

Author:admin Date: 2025-04-08 07:38 Views:80

Introduction

PLCs or programmable logic controllers are specialized computers designed to automate and control industrial processes and machinery. They were introduced to replace the relay-based systems.

Expect to come across a PLC in industrial applications such as petroleum, assembly lines, and power plants. Many businesses use this specialized computer to automate many operations and improve efficiency.

Are you new to PLCs? Not to worry. This guide provides more details about PLCs, including their components, how they work, the types, programming languages they use, and more. Let’s learn more about a PLC below.

Components of a PLC

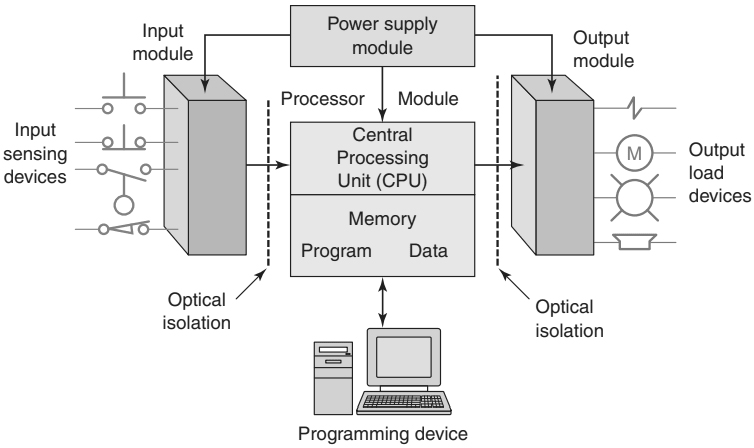

Now that you know what are PLCs, it is good to look at their components to see how they work. Just like any other computer, a PLC will have a power supply, input and output modules, a central processing unit, memory, and a programming device.

The central processing unit, or CPU, is the brain of the PLC. It executes the programmed logic and manages the entire system.

The input/output modules are key for communicating between external devices such as sensors and actuators and the PLC. The input modules receive signals from devices and sensors and provide this information to the CPU for processing.

The output modules send the control signals to the sensors and actuators depending on the input so that the PLC can control the process.

Memory is vital for storing the PLC program and its data. The read-only memory stores the PLC’s essential data and operating system.

The other type of memory is Random Access Memory (RAM), which stores programmed logic ready for execution and temporary data as well.

A programming device is used to program the PLC to perform a particular function depending on where it is set up.

How PLCs Work

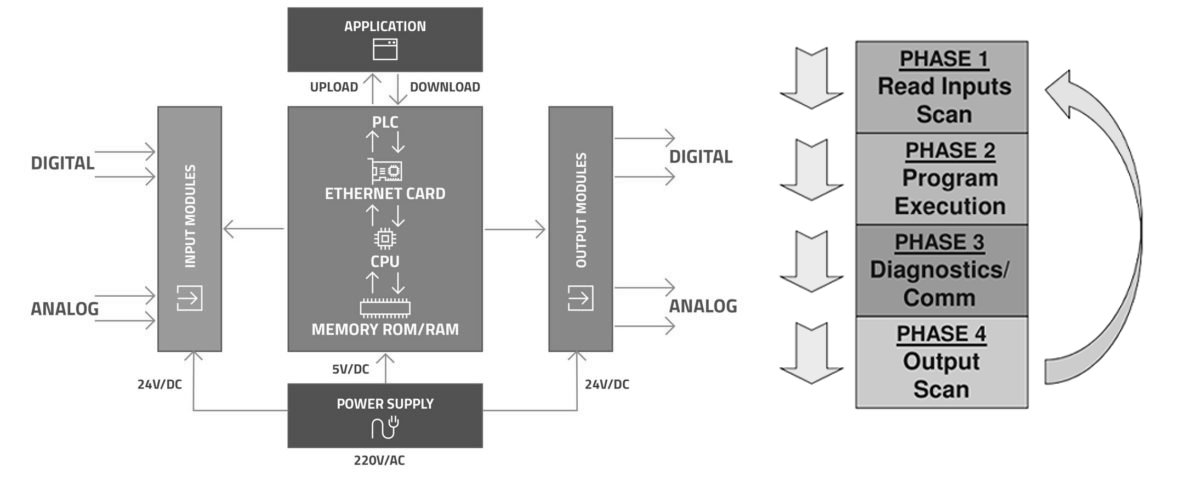

The programmable logic controllers (PLCs) have an easy working mechanism. They first accept input from the sensors and other devices connected to it. Once it gets the information from the input scan, this information is passed to the CPU. Let us say it is for an industrial application. In the first stage, the PLC reads the status of the sensor, such as on/off, high/low, and others.

At the program scan stage, the PLC will execute a command based on the programmed logic. This command sends the signals to the output module.

The output module will update the status of the output devices based on the signals from the CPU. For example, if the input is a temperature sensor, it can signal a valve to open based on the temperature reading.

You can consider a PLC’s workings as a loop. This is where the PLC reads the inputs, executes the program, updates the output, and repeats the whole process again.

The good thing about PLCs is that they can be programmed depending on the application. We will look at how to program PLCs later in the guide.

Features of PLCs

Large or small PLCs all have specific features that make them ideal for various applications.

1. Hardware

The PLC has a modular design, which is essential for expanding and customizing it depending on the application. That is why you can sometimes add or remove the I/O modules as needed.

Still, the hardware is quite robust and reliable. That is how the PLCs can be used in industrial environments where vibrations and impacts are common. The PLCs are still built to be immune to electrical noise.

Reliability also extends to the power supply. It can maintain stable operation even in harsh environments.

2. Programming and Logic

As part of understanding PLCs, you need to know their programming languages. PLCs can support various programming languages. This includes ladder logic and structured text. Depending on the use, you can get other languages being used.

Thanks to programming, the PLCs also offer real-time control. This is because they can quickly change with the input signals and trigger the intended output signals.

A PLC is usually fast in its operations. It can take an average of 50 ms to complete a scan cycle, which includes reading the inputs, executing the programming, and sending the necessary output signals.

3. Communication and Networking

PLCs can communicate with other multiple devices in the system. This is for exchanging data, remote monitoring, and control of the whole system.

They can support different types of communication protocols making it easier to integrate with different types of automation systems.

Modern PLCs feature diagnostic features vital for identifying and troubleshooting issues in the PLC. This is key in minimizing downtimes.

Some models now have safety features that can prevent accidents when certain thresholds are triggered.

Types of PLCs

There are many ways of categorizing PLCs, but we will categorize them based on their hardware setup. In this scenario, we get either fixed or modular PLCs.

Compact or Fixed PLCs

These PLCs are designed as a single unit containing everything, such as the input modules, output models, CPU, power supply, and more. They are more suitable for smaller and simpler applications.

Being compact also makes them cheaper. They are generally less expensive than modular PLCs. They are also easy to install and configure. Having everything in one device definitely simplifies setup and operation as well.

However, they will still have some limitations. The most common is limited expandability, as the I/O points are fixed, so future expansions are limited.

Examples include the Nano PLCs, which are the smallest PLCs you can buy for simple control applications.

Modular PLCs

The term modular means the PLCs are expandable and can be configured based on the user’s needs. In this case, the PLCs come with separate modules. So, you can choose which modules you will be using and combine them to meet specific requirements for an application.

Scalability and flexibility are the biggest advantages of using modular PLCs. You can add and remove modules as per your needs, allowing for ease of customization or expansion.

The features of a modular PLC make it suitable for more complex applications, as it offers the flexibility of customizing it to the application.

Being more customizable also comes with a higher cost. Expect to pay more for such PLCs compared to compact PLCs.

As for applications, such PLCs are common in large scale automation projects such as controlling assembly lines.

Common Applications of PLCs

Industrial Automation

PLCs are common in industrial automation. You will likely find them in manufacturing industries, especially for controlling the assembly lines, robotic systems, and more. The aim is to ensure efficiency and precision.

Process control is also a good use of PLCs. In this case, the PLCs help regulate the temperature, pressure, flow, and other key parameters in an industry.

Building Automation

A PLC can regulate HVAC systems, including ventilation, heating, and air conditioning systems. The result is well-optimized systems that also save on energy use while maintaining a comfortable indoor environment.

Lighting control is another common use of PLCs. They can adjust brightness or switch the lights on and off according to a room’s occupancy.

Expect to still come across them in security systems where they control alarms and other security devices.

Elevators and escalators also need PLCs to control their operations. This ensures that such machinery can operate safely while moving people around.

Other Applications

Traffic control can also rely on PLCs. This leads to optimized traffic flow and reduced congestion.

Water treatment could use PLCs as well. The PLCs would control the pumps, valves, and other equipment in the water treatment process.

PLCs are also vital for steel manufacturing. This includes casting operations and rolling mills to achieve the desired look in the end.

Why Buy PLCs? The Benefits

When someone opts for PLCs, they want to improve on automation and better manage processes. As such, many benefits come with that. Here is what to expect.

- Users experience enhanced efficiency and productivity. For example, once processes are automated, it means less human error and production speed is improved. You also end up with real-time control over the various processes.

- PLCs help in reducing downtimes and maintenance costs. So, PLCs are mostly made for industrial applications, which can often be tough. Well, the PLCs are rugged, offering high reliability vital for minimizing downtime. Modern PLCs also have built-in diagnostics that simplify troubleshooting and maintenance.

- PLCs can be reprogrammed depending on the application. The overall process is easy if you know how to do the programming part. As such, the PLC has increased flexibility to do what you want.

- In addition to flexibility, PLCs are also scalable. This is thanks to the modular nature of PLCs. More modules can be attached to a PLC to expand its functionality based on applications.

- You should expect to experience long-term savings with PLCs. They might cost more in the beginning, but as you keep using them, they will save you a lot. This is because now you get increased efficiency, reduced downtime, and lower maintenance costs.

How are PLCs Programmed? Which Languages are Used?

PLCs use specialized languages and software for programming. Let us start with the commonly used programming languages and then look at the programming process.

Top 5 Most Popular Types of PLC Programming Languages:

- Ladder Diagram (LD) or Ladder Logic – this language resembles electrical relay ladder diagrams. It uses the logic of reading from left to right to control signal flow.

- Structured Text (ST) – it is a text-based language similar to Pascal or C. This is better for writing more complex algorithms.

- Function Block Diagram (FBD) – this is a graphical language that uses blocks to represent functions and connections. It is suitable for modulable programming.

- Sequential Function Chart (SFC) – this is a diagrammatic language vital for programming sequential processes. It shows the steps and transitions in a process.

- Instruction List (IL) – this is a text-based language that uses mnemonics for instructions. It is similar to assembly language.

The programming process for PLCs can follow the following steps.

- Get the software to program the PLC. Download it on your laptop or desktop to start working on the logic or algorithms for the PLC.

- Once the program is ready, upload it to the PLC. Depending on the type of PLC, this is done via a cable connection or network.

- Once the program is loaded, you can connect the PLC to its input and output modules to start testing. Check whether the PLC achieves its intended purpose.

- You can make changes to the algorithm from your laptop and upload it again to the PLC. Some PLCs have the option of online editing, which allows you to change the program while the PLC is still running.

How to Pick the Right PLC for an Application

Choosing the right PLC seems straightforward enough for most people. However, there are a few things to keep in mind that would help you choose appropriately.

1. Understand the tasks the PLC will do

If you understand the functions of PLCs, you will know how to choose the appropriate one. For example, if you need to automate your conveyor belt, you would choose the right PLC with the input and output modules for such a process.

2. System requirements

Determine the project’s input and output needs, which would determine the number of input and output points needed.

Also, the communication protocols are essential. This allows for ease of integration with other devices.

How about the CPU speed and memory? These are vital for assessing the processing power of the unit. It should be fast enough to make it relevant for handling your application.

Scalability is also vital in this part. If you plan on expanding or changing the system, choose a modular PLC for your application.

3. Research the top PLC brands

Several PLC brands are available in the market, but not all of them make the best models. Explore PLCs from top brands such as Schnieder Electric, Siemens, Allen-Bradley, and more. In this case, you are assured of the best quality PLCs.

Consider also the PLC type, depending on what needs to be handled. The options are mostly compact or modular PLCs.

Comparing the features of different PLCs is vital in determining which PLC to buy. Consider their processing power, input and output options, programming language compatibility, and more.

4. Ease of programming

Look at how easy it will be to program the PLC. This means choosing a PLC that supports a user-friendly programming interface and software. Of course, you need to select a unit that supports a language you are comfortable working with.

5. Cost considerations

Evaluate how much it will cost to purchase the PLC and keep it running. The ongoing maintenance costs can determine whether it is a good PLC. You do not need a model that you have to keep replacing something to keep it running.

You can always find a good PLC within your budget or keep it flexible, as sometimes you may need to spend more to get a better choice.

Conclusion

The best PLC allows you to automate processes and improve production efficiency. Picking the best PLC is crucial for running various processes. As such, we recommend buying from top brands as always. Still, make sure you buy based on your needs. This allows you to fully use the PLC to improve your work. Follow any maintenance routines given by the manufacturer for the best PLC performance.