What is a Contactor? Understand Its Function, Types, and Uses

Author:admin Date: 2025-03-15 08:53 Views:65

When you start looking at electrical switches, chances are you will come across some designs you have not heard of before. Some are more complicated than others, but that design makes them the right fit for the job. Contactors are some of the electrical devices whose job can be as simple as switching on or off a circuit, but there is more to that. Let us learn more about contactors below.

What is a Contactor?

A contactor can be described as an electrical device that is used for switching on and off a circuit. It is sometimes considered a relay, but there are a few differences between the two. Contactors are mostly used for applications that work with high currents while relays will be found in low current applications.

There are multiple types of contactors in the market. They are mostly categorized based on application, type of current, and number of poles. You will come across contactors in applications such as thermal evaporators, heating systems, motors, and other types of electrical loads.

How Does a Contactor Work

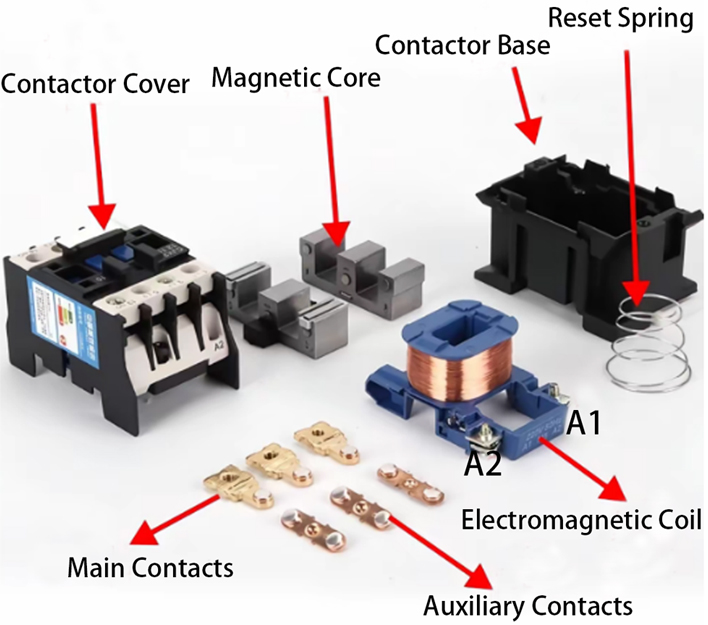

contactor components

Whether it is an AC contactor or DC contactor, expect them to have similar components. These components are going to help us learn more about how contactors work.

The main components of any contactor include the coil, enclosure, and contacts.

The coil is set up in an electromagnet field, which provides the driving force, key in closing the contacts. The coil has two parts: movable and fixed parts. The movable part has a spring connected to it. Once the electromagnetic force is higher than that of the spring, it closes the contacts and vice versa.

The contacts are the conductive pieces that close and open to control current flow. Because the device is likely to be used many times, the contacts are built to withstand arcing and wear.

You also get the enclosure, which protects the coil and provides insulation in case someone touches it. It also prevents dust, oil, and other hazards from affecting the contactor’s performance.

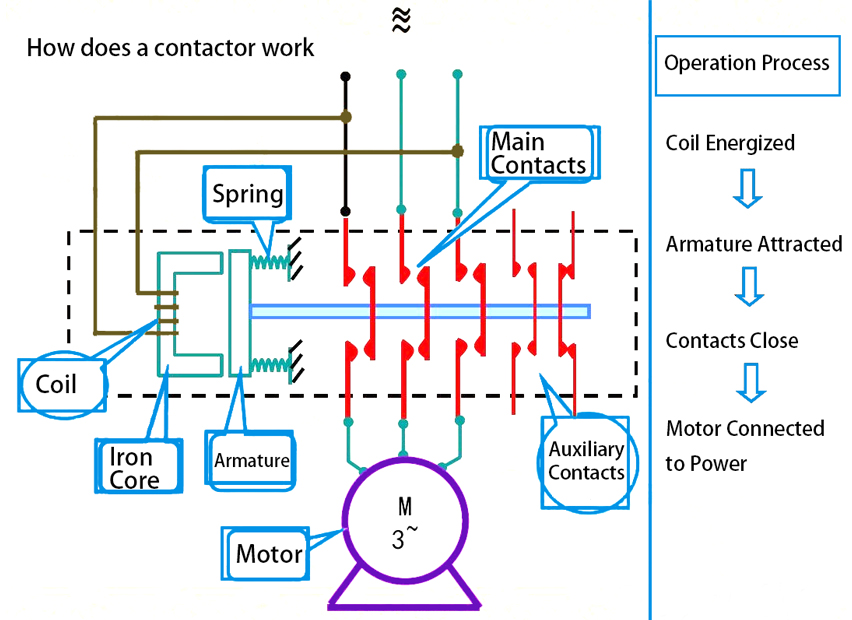

In terms of how a contactor works, it is quite straightforward. The excited electromagnetic core creates a magnetic field when the current goes through the contactor. This is what moves the contactor armature to close contact. Now that the contact is closed, current can reach the load.

The coil is de-energized if the current is removed, resulting in no magnetic force. The spring force is now higher, pulling the armature back. This leads to an open circuit, meaning no current reaches the load.

Types of Contactors

When you are in the market for contactors, it is possible to come across many options. The manufacturers can categorize them based on type of current, number of poles or application.

Type of Current

AC (alternating current) Contactors

As the name suggests, AC contactors are designed to work with AC circuits and fluctuations in AC power. They have an iron core and a shading coil to help prevent chattering.

Expect to come across such contactors in industrial machinery and HVAC systems.

DC (direct current) Contactors

These are different from AC contactors based on the type of current they work with. In this case, the current flow is unidirectional, unlike in AC, where the current can periodically reverse direction.

The core will mostly be made of soft steel and will be built to be more robust than AC contactors. Expect them in electric vehicles, industrial DC motors, and renewable energy systems.

Number of Poles

Single pole contactors

These are contactors designed to control one circuit. They are mostly found in simple circuits, such as those powering small HVAC systems.

2-pole contactors

These can control two circuits, which is a common option for HVACs that require switching between the heating and cooling phases.

3-pole contactors

In this case, the contactor controls three circuits, which is another reason it is used for three-phase applications. This is a common device in industrial applications. For example, it can be used to control a three-phase motor to ensure a balanced operation.

You get the idea by now. Depending on the application, getting even 4-pole contactors or more is possible.

Uses of Contactors

Electrical contactors have many applications, the most common of which is motor control. Depending on their use, contactors are commonly used to start and stop motors, and some are used to reverse the direction of AC motors.

You can still use them in the HVAC system. Let us say it is a 3-pole contactor that controls the HVAC system’s operation. This is where it controls the compressor, fans, and other system components, whether for residential or commercial setup.

Industrial machines could also use contactors, especially when operating heavy machinery such as conveyor belts.

A Schneider contactor can also be used to manage power distribution. An example is to use the contactors as remote-controlled switches. Here, you can isolate part of the circuit depending on the demand.

Other applications of contactors include lighting control for activating and deactivating light fixtures based on certain parameters. Expect to still come across contactors in automation and robotics systems to control how they work.

How to Install Contactors

Whether you are installing lighting contactors or motor contactors, the process is often the same. Here is how you can do it.

- Choose the right contactor for the project. Examine the contactor’s technical specifications to determine whether it is suitable for the project.

- Select the right installation location. It should be free from direct sunlight, excess moisture, and dust. However, ensure you provide adequate ventilation to prevent overheating and maintain a consistent temperature.

- Align the contactor with the DIN rail. Press it firmly until it clicks into position.

- Go ahead and wire it correctly depending on what you need powered. Getting this step right is critical or it can be an electrical hazard.

- Once the wiring is done, proceed to test the connection and see if it works as expected. Adjust according where necessary.

We still insist that you get a professional electrician to help with installation and wiring of the contactor to avoid creating an electrical hazard.

Safety Tips for Handling Contactors

The most obvious safety tips that people might neglect are simply turning off the power before you start working on the contactors. Let us say you want to install a new contactor and ensure the circuit’s power is turned off.

When working with contactors, use the correct tools and equipment, including wire strippers, screwdrivers, and more. Worn-out tools can lead to disasters, such as electrical shocks.

Regularly inspecting the electrical connections will ensure that your magnetic contactor works as expected. If you come across a connection that is loose, go ahead and tighten it.

You should also stop overloading circuits, as this can cause overheating or electrical fires. Choose a contactor designed to work with the electrical load to prevent such issues.

Always test your electric contactor after installation. This helps make necessary adjustments to keep the contactor working just as you want.

Choosing the Correct Contactor

You could be looking to choose a contactor for an air conditioner, motor, or any other application. It is key that you choose correctly, or else the contactor will not work as expected. Here is how you choose.

Power Rating and Load Requirements

Look at the load requirement for your application first. Use that information to check against the power rating of the contactor. You can easily access this information from the contactor’s technical specifications sheet.

Choosing the correct sizing means you would not have to worry about issues such as overheating or overloading the contactor.

Load Type

Remember, different contactors are designed to work with different devices. For example, you should not use an AC contactor for DC applications. Identify where you will be using the contactor and now choose the correct one for the job.

Contactor Configuration

You should also buy the contactor based on its configuration. In this case, we mean if it is normally open, normally closed, or based on the number of poles. The configurations are vital based on the appliance.

For example, you need at least a 3-pole contactor for an industrial motor to help properly work the device.

If you are unsure of the configuration you should pick, consulting a qualified electrician can help.

Environmental Factors

Where are you going to install the AC or DC contactor? Look at things such as the operator temperature range as it can determine if the contactor will work in those conditions or not. Also, is the contactor built to withstand humidity and vibration? As such, only choose a model you are confident it can handle such conditions.

Brand Reputation

You are likely to come across many contactors in the market. Buying from a top brand is highly recommended. Some of the top brands include Schneider Electric, Siemens, ABB, Allen Bradley, TE Connectivity, Eaton, and Lovato.

Do more research to find other brands that give you good value for money, ensuring your application works without fail.

Maintenance Tips for Contactors

Getting Siemens contactors can be beneficial, but how do you ensure they remain in good working condition? Here are some maintenance tips for contactors.

- Check visually for damage. If the contactor is too worn, it is time to get a new one.

- Consider cleaning to remove dust and debris from the contactors. This helps keep them well ventilated so they can keep working correctly.

- Do a mechanical inspection to see if the moving parts move smoothly and freely. If the contactor has not been working smoothly lately, check to see what could be the issue.

- Do electrical tests on the circuit. This includes continuity tests, resistance tests, and overcurrent tests. If the contactor passes all these tests, you know it works just right.

- We also recommend preventing overloading the contactor if you want it to keep switching correctly. Also, proper wiring is necessary to ensure the circuit is completed correctly.

Conclusion

You can choose contactors today knowing how important they are at completing circuits. Many devices out here require contactors to keep them running smoothly. Ensure you get the right contactor so the device will keep working as expected. Good maintenance is also necessary to keep the contactor in good shape and working with your load connected to it.